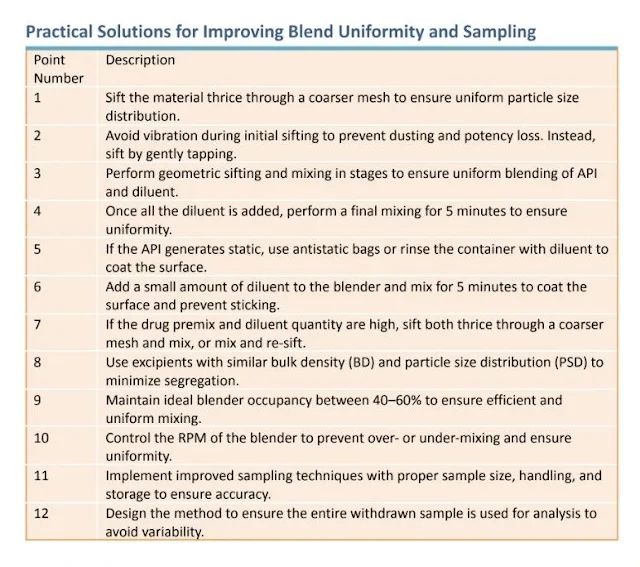

1. Sift the material thrice through a coarser mesh to ensure uniform mixing.

2. Avoid vibration during initial sifting:

- Do not use vibration in the sifter during the initial stages, especially when the drug quantity is high.

- Using vibration at this stage may cause dusting of the drug, leading to potency loss and uneven distribution.

- Instead, perform sifting by gently tapping to prevent excessive dust generation.

3. Perform geometric sifting and mixing:

- For example, if you have 1 kg of API, sift it with 2 kg of diluent thrice and mix in the blender.

- Take out the blend, then mix it with 6 kg of diluent.

- Continue this process stepwise until all the diluent is added and mixed.

4. Once all the diluent is added, perform a final mixing for 5 minutes to ensure uniformity.

5. If the API tends to generate static:

- Use antistatic bags for handling and mixing.

- Alternatively, rinse the polybag or blending container with a small amount of diluent to coat the surface.

6. Add a small amount of diluent to the blender and mix for 5 minutes to coat the blender's surface, ensuring the API does not stick to the walls.

7. If the drug premix and diluent quantity are very high:

- Sift both the premix and the diluent thrice through a coarser mesh and mix.

8. Use excipients with similar bulk density (BD) and particle size distribution (PSD):

- This minimizes segregation and ensures better blending uniformity.

9. Maintain ideal blender occupancy:

- Ensure the blender is filled to 40–60% of its capacity for efficient mixing and to avoid over- or under-blending.

10. Control the RPM of the blender:

- Optimize the blender's speed to prevent over-mixing (leading to segregation) or under-mixing (causing poor uniformity).

- Typically, a lower RPM is suitable for sensitive blends, while higher RPM may be used for less cohesive materials.

11. Improved Sampling Technique:

- Ensure the entire withdrawn sample is used for analysis to avoid variability caused by partial sampling.

- Take a correct sample size, usually X to 3X of the required amount.

- Use glass vials for sampling. If sampling on butter paper, ensure the full material is transferred into a vial.

- Keep vials upright and use a vial cage to prevent them from falling.

- Rinse vials during analysis with diluent for complete extraction.

- Perform triplicate sampling to cross-check results.

- Store samples under proper conditions to maintain integrity.

- Never collect samples on butter paper, as material may stick or fall from packets.

- Use antistatic stoppers when sampling with vials to prevent static charge effects.

12. Design the method to avoid partial sampling:

- The method should ensure that the entire sample withdrawn is used for analysis, as partial sampling can lead to variability and inaccuracies.

- Blend Uniformity Analysis

- Data-Driven Sampling Plan for Uniformity of Dosage Unit

- Differences Among Blend Uniformity, Content Uniformity and Weight Variation