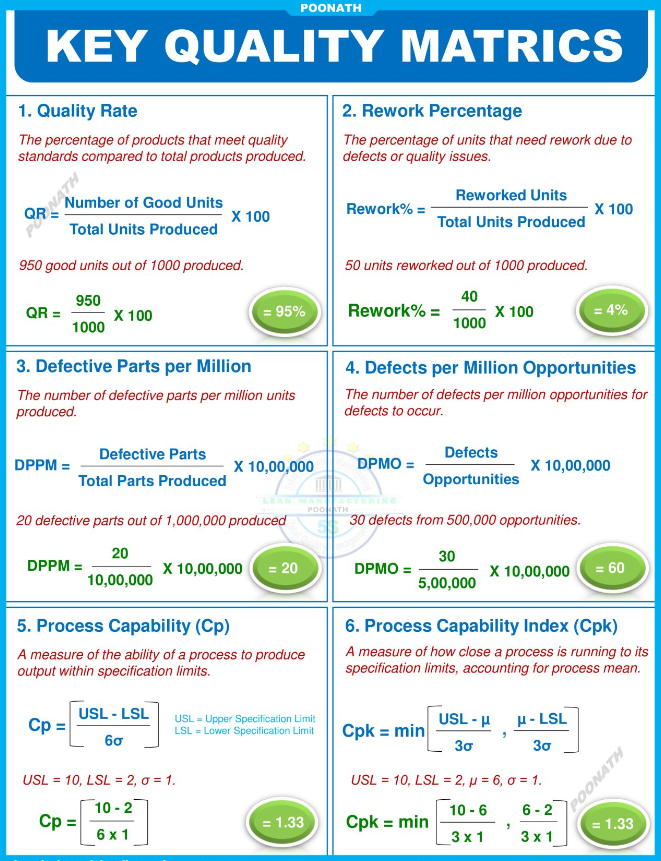

1. Quality Rate

What It Is: This tells us the percentage of products or services that meet quality standards.

How to Improve:

· Train employees regularly on what quality means.

· Keep clear procedures in place for everyone to follow.

Why It Matters:

· Happy customers love high-quality products!

· Helps pinpoint where we can do better.

2. Rework Percentage

What It Is: This measures how many units need fixing to meet quality standards.

How to Improve:

· Set up quality checkpoints during production.

· Equip employees with the right training and tools.

Why It Matters:

· Cuts down on extra costs from reworking.

· Makes the whole process more efficient.

Read also: Key Manufacturing Practice

3. Defective Parts per Million (DPPM)

What It Is: This counts how many defective parts are produced per million.

How to Improve:

· Regularly check and inspect production processes.

· Use data to spot trends and issues.

Why It Matters:

· Helps us compare against industry standards.

· Tracks how our quality improves over time.

4. Defects per Million Opportunities (DPMO)

What It Is: This shows the number of defects per million chances for defects to happen.

How to Improve:

· Use methods like Six Sigma to improve processes.

· Train employees on best practices to avoid errors.

Why It Matters:

· Gives a complete picture of quality.

· Helps focus on the most critical areas for improvement.

5. Process Capability (Cp)

What It Is: This measures how well a process can produce items within set limits.

How to Improve:

· Review and tweak process controls regularly.

· Investigate variations to keep things consistent.

Why It Matters:

· Shows how well we can meet quality specs.

· Helps make smart decisions for adjustments.

6. Process Capability Index (Cpk)

What It Is: This looks at how close a process is running to its limits, considering both the average output and variation.

How to Improve:

· Keep an eye on process performance to catch shifts early.

· Foster a culture of ongoing improvement.

Why It Matters:

· Provides a clearer picture of how a process performs.

· Helps identify urgent and long-term improvement needs.

Read also: Process Capability Index Calculation

Resource Person: Poonath Sekar